Exactly how to Choose the very best Heat Transfer Fluid for Industrial Applications

Exactly how to Choose the very best Heat Transfer Fluid for Industrial Applications

Blog Article

How Warmth Transfer Liquid Adds to Lasting and Cost-efficient Procedures

In the contemporary commercial landscape, the role of warm transfer liquids (HTFs) in advertising lasting and cost-efficient procedures can not be overstated. These liquids are critical in optimizing thermal administration systems, consequently dramatically boosting power effectiveness and reducing functional costs. heat transfer fluid. The environmental advantages of innovative HTFs, with their high thermal stability and low poisoning, are indisputable.

Understanding Warmth Transfer Liquids

In the realm of thermal monitoring, warm transfer fluids (HTFs) serve as necessary representatives for transferring thermal power from one location to one more. These fluids play a crucial role in various industrial applications, consisting of chemical processing, power generation, and HVAC systems.

The structure of warm transfer fluids can differ considerably, consisting of choices such as mineral oils, artificial oils, glycols, and molten salts. Each type supplies distinctive benefits, such as boosted thermal stability, reduced viscosity, and high boiling factors, which are chosen based on specific functional requirements. The choice of HTF impacts not only the effectiveness of heat transfer however additionally the long life and safety and security of the system in which it is employed.

As markets proceed to innovate, the growth of advanced HTFs, characterized by their boosted thermal conductivity and lowered environmental impact, is essential for fulfilling the demands of modern thermal management challenges.

Enhancing Power Effectiveness

Improving energy efficiency has become a paramount issue across various markets, motivating a more detailed exam of warm transfer fluids' function in maximizing thermal monitoring systems. These fluids are essential to preserving the wanted temperature level in procedures, thereby minimizing energy waste and enhancing overall system efficiency. By choosing an appropriate heat transfer fluid, industries can substantially boost their energy efficiency, bring about lowered energy intake.

Advanced formulations of warm transfer liquids have been developed to withstand severe temperatures while preserving stability and efficiency. These technologies expand the functional lifespan of the fluid, minimizing the regularity of substitutes and energy-intensive upkeep tasks. The usage of synthetic or bio-based fluids uses extra advantages in terms of decreased ecological influence, lining up with international sustainability goals. Consequently, improving power performance via optimum warm transfer liquid selection is not only a technological requirement but additionally an environmental necessary.

Reducing Functional Prices

Operational prices are a considerable consideration for markets looking for to keep affordable benefit, and the selection of warmth transfer fluid plays a vital function in expense monitoring. Picking a proper warmth transfer fluid can cause significant cost financial savings by boosting system efficiency and reducing energy intake. High-performance liquids minimize thermal deterioration, which in turn lowers the frequency of fluid replacement and downtime related to upkeep, consequently lowering operational expenses.

In addition, warm transfer fluids with superior thermal security and rust resistance extend the lifespan of tools. This minimizes the demand for regular try this web-site repair work and substitutes, which can be pricey and turbulent to procedures. By buying high-quality fluids, sectors can achieve long-term decreases in upkeep expenses and boost the integrity of their systems.

In addition, advanced warmth transfer fluids usually exhibit lower thickness at operating temperature levels, which improves pump effectiveness and reduces power use in liquid blood circulation. This optimization of power consumption straight equates into decreased functional expenses. Furthermore, numerous contemporary warmth transfer liquids are engineered to operate properly over a broad temperature variety, lowering the demand for numerous fluid kinds, therefore enhancing inventory requirements and reducing associated prices. These variables jointly add to even more sustainable and economical procedures.

Ecological Influence Reduction

The push in the direction of decreasing ecological impact has actually gotten momentum in markets leveraging warmth transfer fluids. Business are increasingly identifying the value of minimizing eco-friendly footprints by taking on lasting practices. Heat transfer liquids (HTFs) play a crucial function in this transition, providing chances to boost power effectiveness and minimize emissions. By selecting HTFs with high thermal security and reduced poisoning, sectors can ensure minimal leak and deterioration, thus minimizing harmful ecological launches.

Furthermore, making use of sophisticated warmth transfer liquids adds to enhanced system efficiency, minimizing the overall power usage. This reduction not only leads to expense savings but also decreases carbon dioxide discharges, assisting in the fight versus environment modification. Fluids that are eco-friendly and recyclable even more boost sustainability efforts, as they reduce waste and promote circular economic situation practices.

Furthermore, including HTFs into closed-loop systems prevents fluid loss and contamination of the surrounding environment. This strategy find more info makes certain that liquids are reused, decreasing the demand for new sources and limiting waste generation. By welcoming these ecologically conscious strategies, sectors can considerably diminish their environmental impact while keeping high functional effectiveness, lining up with global sustainability goals and regulatory needs.

Selecting the Right HTF

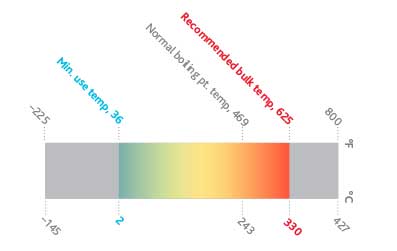

Selecting the suitable heat transfer original site liquid (HTF) is an essential step in progressing ecological sustainability within commercial procedures. The choice of HTF straight influences system performance, energy intake, and environmental impact. A perfect HTF ought to have a high thermal capability, reduced thickness, and high thermal conductivity to make sure efficient heat transfer. In addition, its stability over a wide temperature level range is vital to stop degradation, which can bring about boosted exhausts and waste.

This guarantees long life and decreases maintenance costs. The fluid should be safe and eco-friendly, lessening its environmental impact and ensuring compliance with ecological guidelines.

Conclusion

Report this page